Baking and food industry gas burners

In the baking and wider food industry, gas burners are a key component in achieving high efficiency through precise control of cooking processes. Used in baking ovens and specific machinery for drying, roasting, or cooking, these industrial burners allow exact temperature management at every production stage — a crucial factor in obtaining high-quality products.

The use of professional gas burners is also a strategic choice in terms of energy savings and production versatility. Their technical flexibility allows them to effortlessly adapt to various production processes in the food industry: a sector where the range of applications is extremely wide.

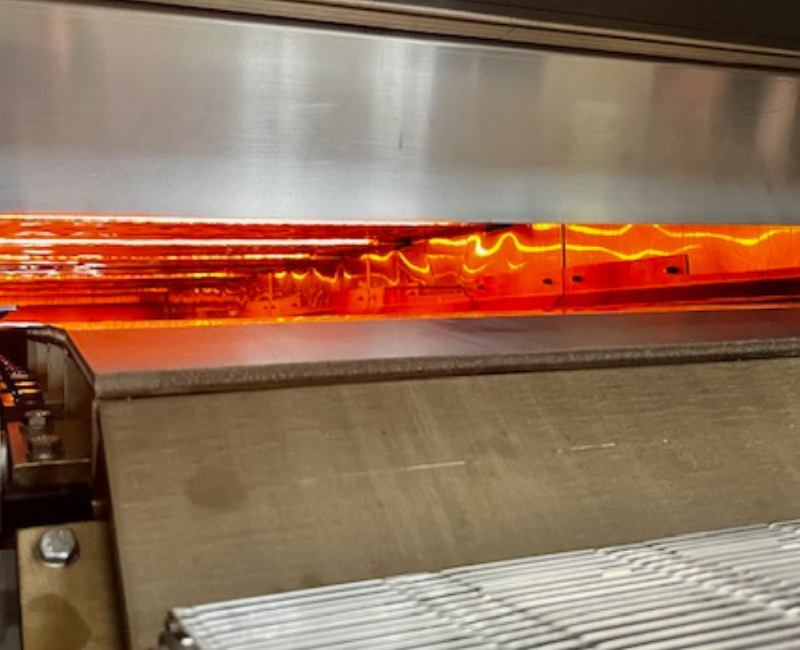

Industrial gas burners differ from electric heating methods in their ability to produce constant, uniform heat, transmitted by radiation, ensuring optimal heat distribution. This is particularly important in baking ovens, where each type of product — bread, pizza, or pastry — requires carefully controlled temperatures and timing. Thanks to their rapid heating response and ability to maintain high temperatures, industrial gas burners are ideal for large-scale applications, reducing production times while ensuring consistently high quality.

In the context of the food industry, efficiency is naturally a key factor. Reducing energy consumption without compromising performance is a top priority for every company in the sector.

This is why SIABS gas burners have been designed to provide advanced solutions that meet the specific needs of the food industry. Their design ensures accurate flame control and precise heat output, with a strong focus on energy savings and environmental sustainability.

Another reason why gas burners are so popular in the food industry is their reliability. These systems are designed to withstand long operating cycles without compromising heat quality, making them a strategic choice not only for bakeries, but for all food production facilities where continuous operation is essential.

SIABS solutions for professional baking ovens and food industry machines

After understanding the advantages of gas burners for baking and food production, it’s worth exploring the specific solutions developed by SIABS to meet these needs.

The company offers a range of industrial gas burners designed to enhance oven and bakery machinery performance, ensuring superior temperature control and adaptability across various applications.

In fact, SIABS radiant heating technology not only provides efficient and precise temperature control, but also perfectly integrates it into professional systems, with specific features for each type of application.

One of the major strengths of SIABS burners is their customization capability. Modular configurations allow the creation of systems specifically designed to meet the precise requirements of industrial ovens and baking machines. This feature is particularly appreciated in production processes where a controlled temperature curve is essential to achieve the desired cooking results.

SIABS industrial gas burners also ensure uniform heat distribution, allowing professionals to achieve products that retain their ideal texture and organoleptic qualities.

For bread and pizza ovens, SIABS has developed specific burner systems that ensure even baking at optimal temperatures. Thanks to localized radiant heat distribution, every part of the product achieves the desired browning and consistency — from the crust’s crispness to the crumb’s softness. SIABS systems maintain the required heat levels even during extended, high-intensity production cycles.

SIABS gas burners: efficiency and customization for industrial baking

Having examined the technical characteristics and versatility of SIABS gas burner solutions for industrial and bakery ovens, let’s look at how these systems improve operational efficiency across different industrial applications.

In the baking industry, where large-scale production demands speed, consistency, and quality, SIABS gas burners are an essential ally for improving product quality, reducing energy consumption through the advantages of radiant heat, and optimizing the entire production process.

Thanks to their ability to provide homogeneous and adjustable heat, SIABS burners ensure that every product undergoes perfect baking, browning, drying, roasting, or caramelization — eliminating issues caused by temperature fluctuations or uneven heat distribution.

The use of industrial gas burners minimizes energy consumption, ensuring that every unit of energy used is utilized optimally, thereby reducing operating costs. This is a significant advantage for companies that operate on a large scale.

In conclusion, SIABS professional gas burners represent a smart, cost-effective choice for companies aiming to improve industrial performance.

Contact us today to find out how we can help you optimise your food or bakery production systems.