Why participating in the IBA trade show is strategic for innovation in baking

The IBA trade show as an international hub for food technology

From May 18 to 22, 2025, SIABS took part in the IBA trade fair in Düsseldorf, one of the world’s leading events for the bakery and confectionery industries. For professionals developing industrial baking technologies, IBA is not just a showcase — it’s the beating heart of innovation. Here, the most advanced equipment manufacturers, technical managers of major food groups, quality specialists, and plant designers come together.

Attending IBA means engaging directly with the real needs of industrial bakeries around the world, discovering the latest technological trends, and gathering valuable feedback to refine future solutions. The dialogue with global industry leaders reveals the key market priorities — greater efficiency, flexibility, sustainability, and consistent product quality.

In this competitive and highly technical context, SIABS stood out for its consulting approach and focus on customized solutions. Our experts showed visitors how radiant gas burner technology can be the key to achieving concrete results in terms of performance and energy savings.

The SIABS approach to innovation in baking burners

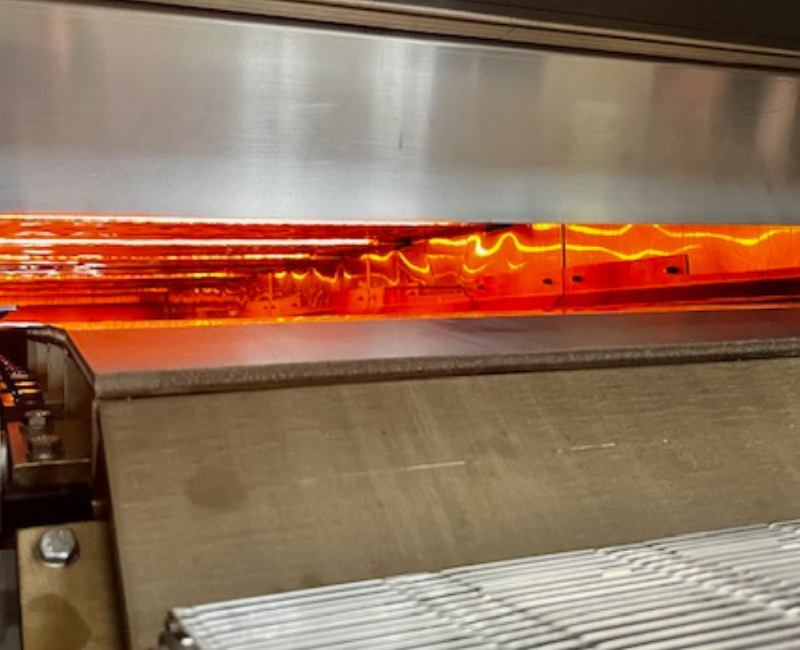

At the SIABS booth, the spotlight was on radiant burners for industrial ovens, designed to enhance productivity in medium and large-scale bakeries. We presented systems built with high-temperature resistant materials, modular power control systems, and advanced combustion technologies to ensure optimal operation and minimal NOx and CO emissions.

The goal is not only to provide an efficient component for an industrial baking plant, but to deliver a complete heating solution precisely adapted to the oven’s structure, the type of product being baked, and production rhythm. This philosophy attracted strong interest from many operators seeking reliable, sustainable, and customized technological partners.

Through our participation at IBA, SIABS reaffirmed its commitment to continuous innovation and direct collaboration with those who work every day to produce high-quality bread and baked goods worldwide.

SIABS radiant gas burners for baking ovens: key advantages and technologies

Uniform baking and superior product quality

As mentioned in our overview of the IBA trade fair 2025, one of the key topics addressed by SIABS concerns the quality of baking in industrial ovens. The radiant gas burners developed by SIABS are designed to ensure even heat distribution, which is undoubtedly one of the most critical factors in the large-scale production of bread, pizza, focaccia, and other baked goods.

Uneven baking can cause waste, visible defects, and texture inconsistencies, directly impacting customer satisfaction. SIABS burners eliminate these issues through controlled radiant heating, which acts directly on the product’s surface, ensuring uniform browning and consistent crumb structure in every batch.

Unlike forced convection systems, radiant heating does not drastically alter ambient humidity, allowing the baking process to fully respect fermentation and moisture parameters — even for delicate recipes. The result is greater product stability and quality, crucial for industrial bakeries operating continuously where every second and degree matter.

Modular control, energy efficiency, and low emissions

Beyond product quality, our radiant gas burners offer major advantages in energy efficiency. The premix system, featuring a stainless-steel chamber and metallic fiber combustor, enables precise thermal power control, adaptable to multiple oven zones and production stages. This reduces energy consumption while optimizing heating and cooling times between batches.

From an environmental perspective, SIABS burners are engineered to meet the strictest emission standards, maintaining extremely low NOx and CO values through advanced gas premixing and controlled combustion.

At IBA, these features drew the attention of many international operators seeking sustainable, high-performance, and durable baking technologies. In this context, SIABS burners confirmed their role as a key enabler for the next generation of industrial ovens.

Customized solutions and technical consulting: the added value of SIABS

Custom design for new or existing ovens

One of the most appreciated aspects of SIABS’s presence at IBA was our ability to custom-design each project according to the client’s specific needs. At SIABS, we never propose off-the-shelf solutions — each gas burner system is carefully developed based on the oven layout, chamber dimensions, tray configuration, and final product characteristics.

This flexible design approach is especially valuable not only for new plants but also for retrofitting existing ovens, where improving performance without replacing the entire structure is often essential. In these cases, our technical team performs a detailed operational analysis to plan targeted interventions such as:

- integrating new radiant burners,

- dividing the oven into independent zones,

- optimizing heat distribution, or

- upgrading control systems.

Each burner component is also designed for easy integration and maintenance, minimizing downtime. This approach ensures measurable improvements in efficiency, lower energy consumption, and higher production quality — all while maintaining uninterrupted operations.

A tech partner for industrial bakery growth

For SIABS, delivering a product means far more than supplying technology — it means becoming a partner for growth. We provide full support from design and commissioning to staff training and after-sales service.

Our technical department works side by side with clients through every phase: site inspections, operational simulations, material selection, and precise system sizing.

Our consulting services extend beyond thermotechnical aspects to include energy strategy and environmental compliance, giving industrial bakeries a concrete competitive advantage in increasingly sustainability-driven markets.

At the IBA fair 2025, we built new partnerships with both Italian and international companies who see SIABS not just as a supplier, but as an ally in innovation. This is our added value: combining technical expertise with attentive listening and the drive to create solutions that truly perform — every day, in real ovens and production lines.