Industrial Burners for Heat Treatment

Custom-Designed Industrial Burners with Premix Technology

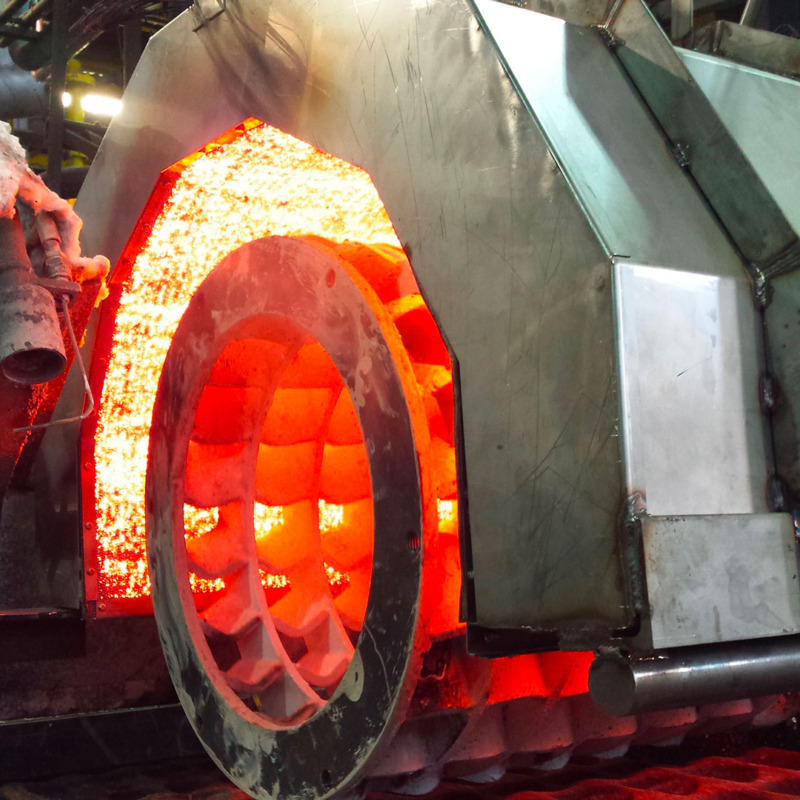

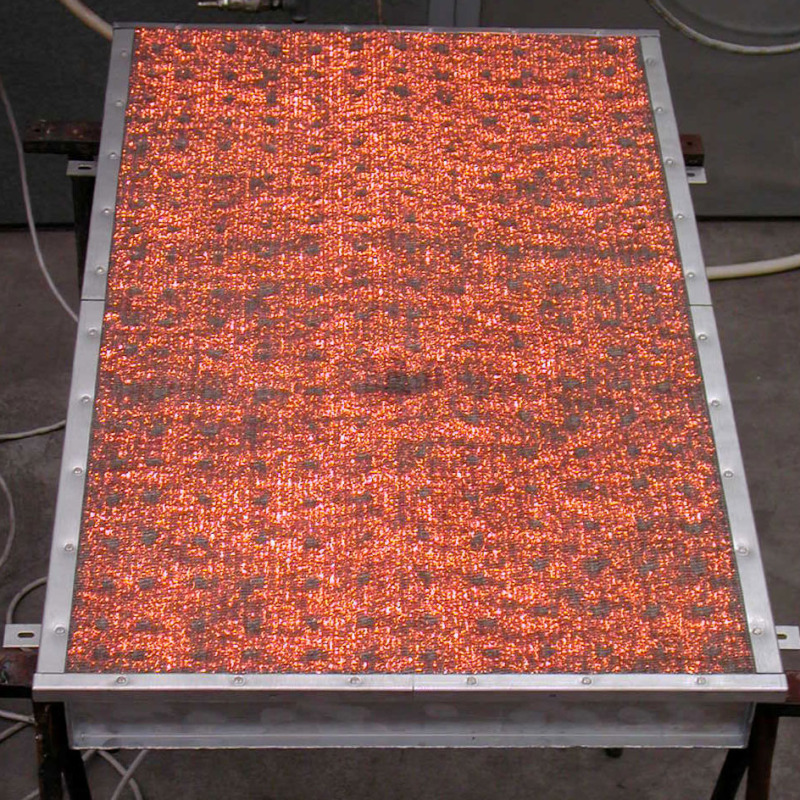

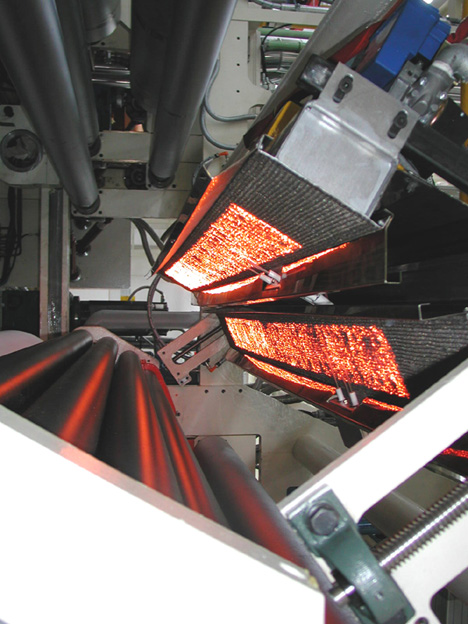

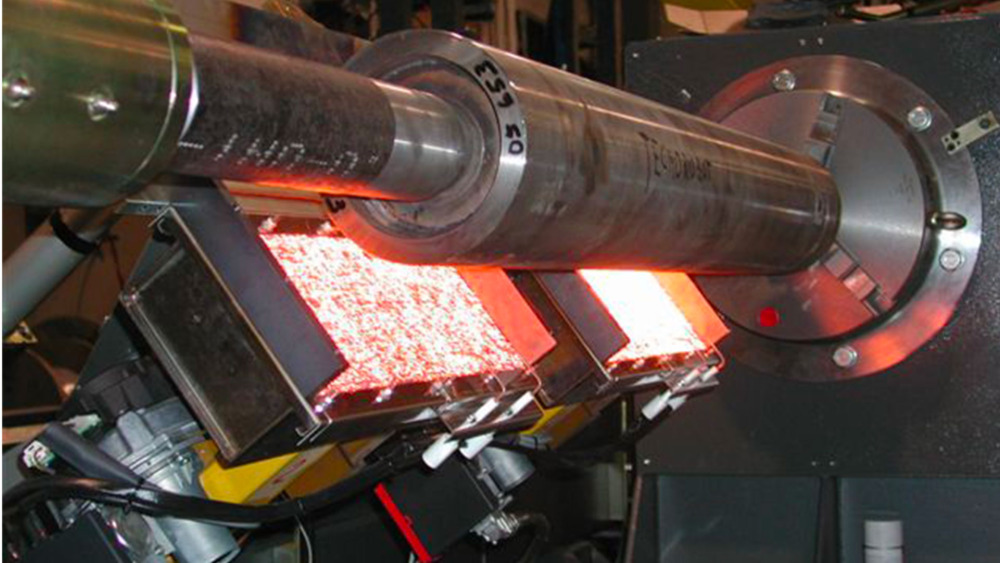

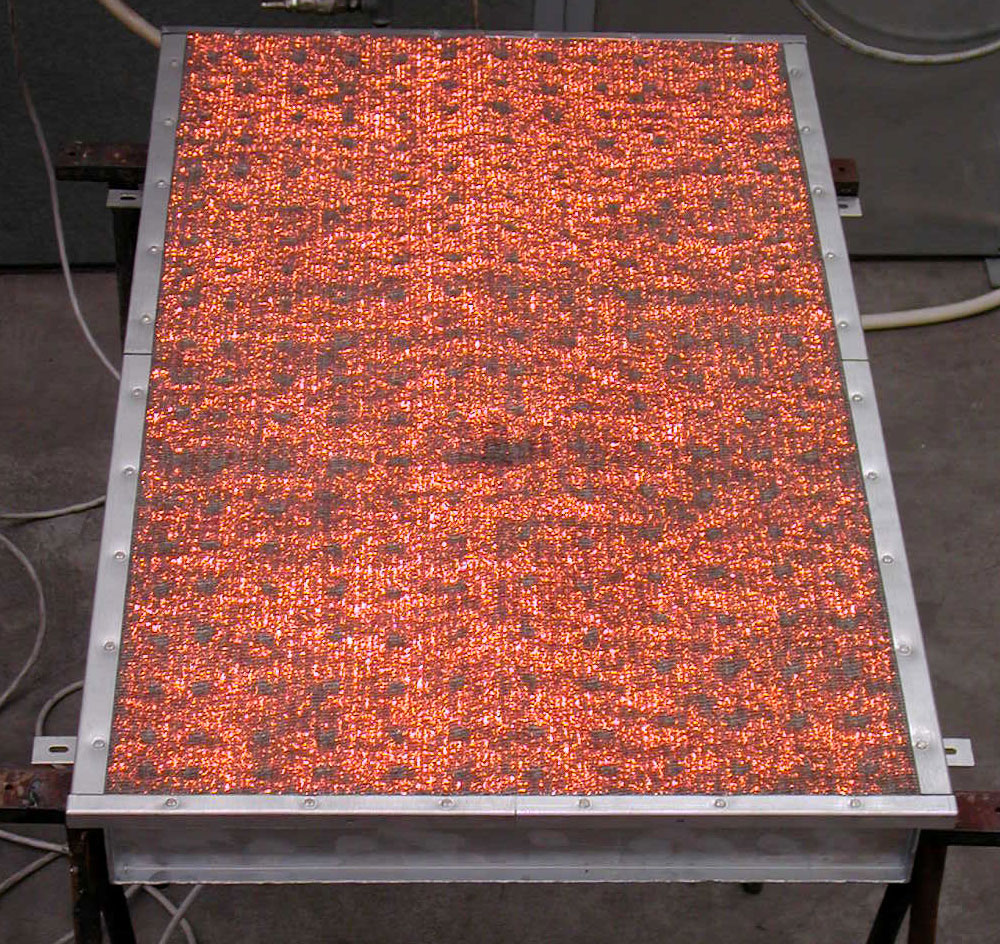

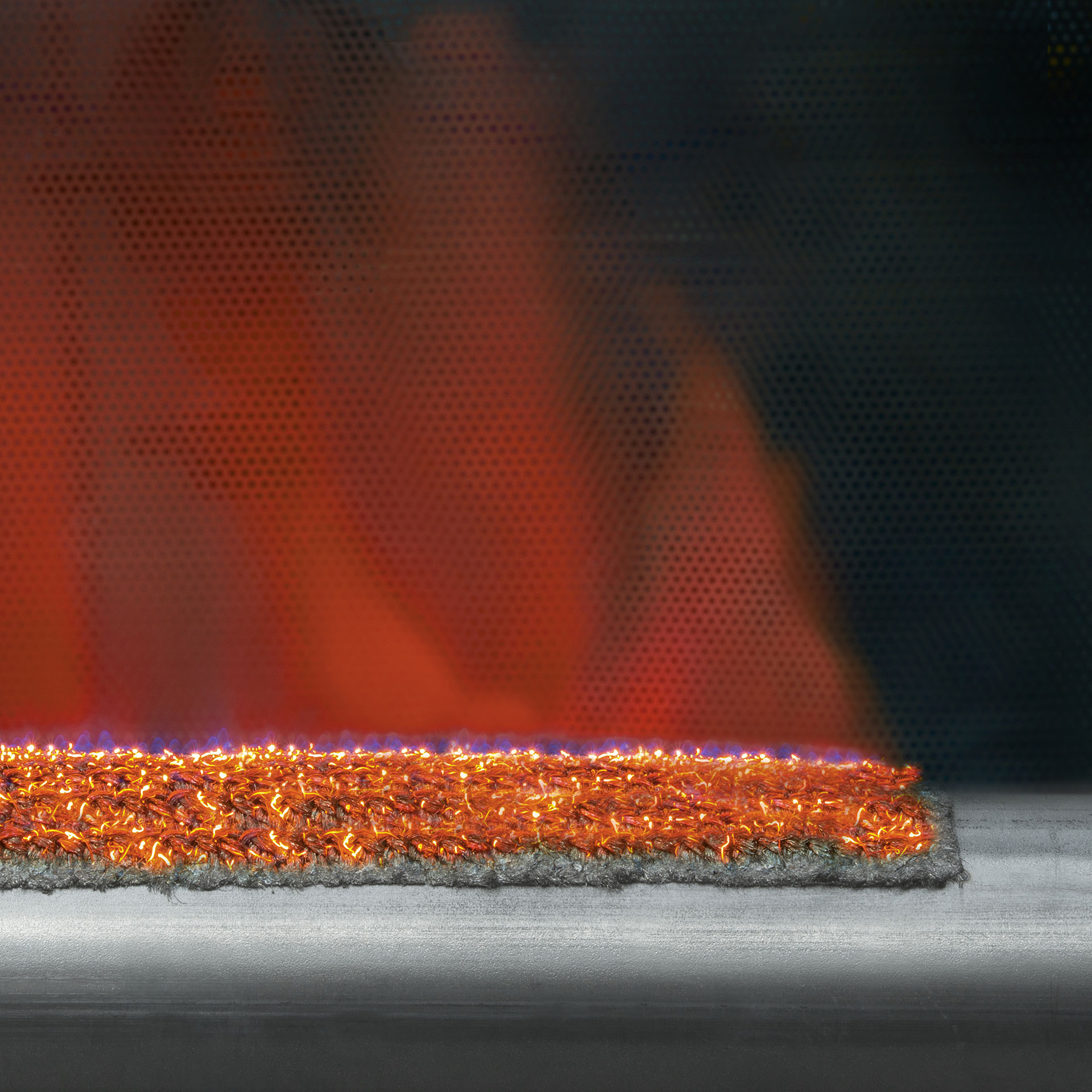

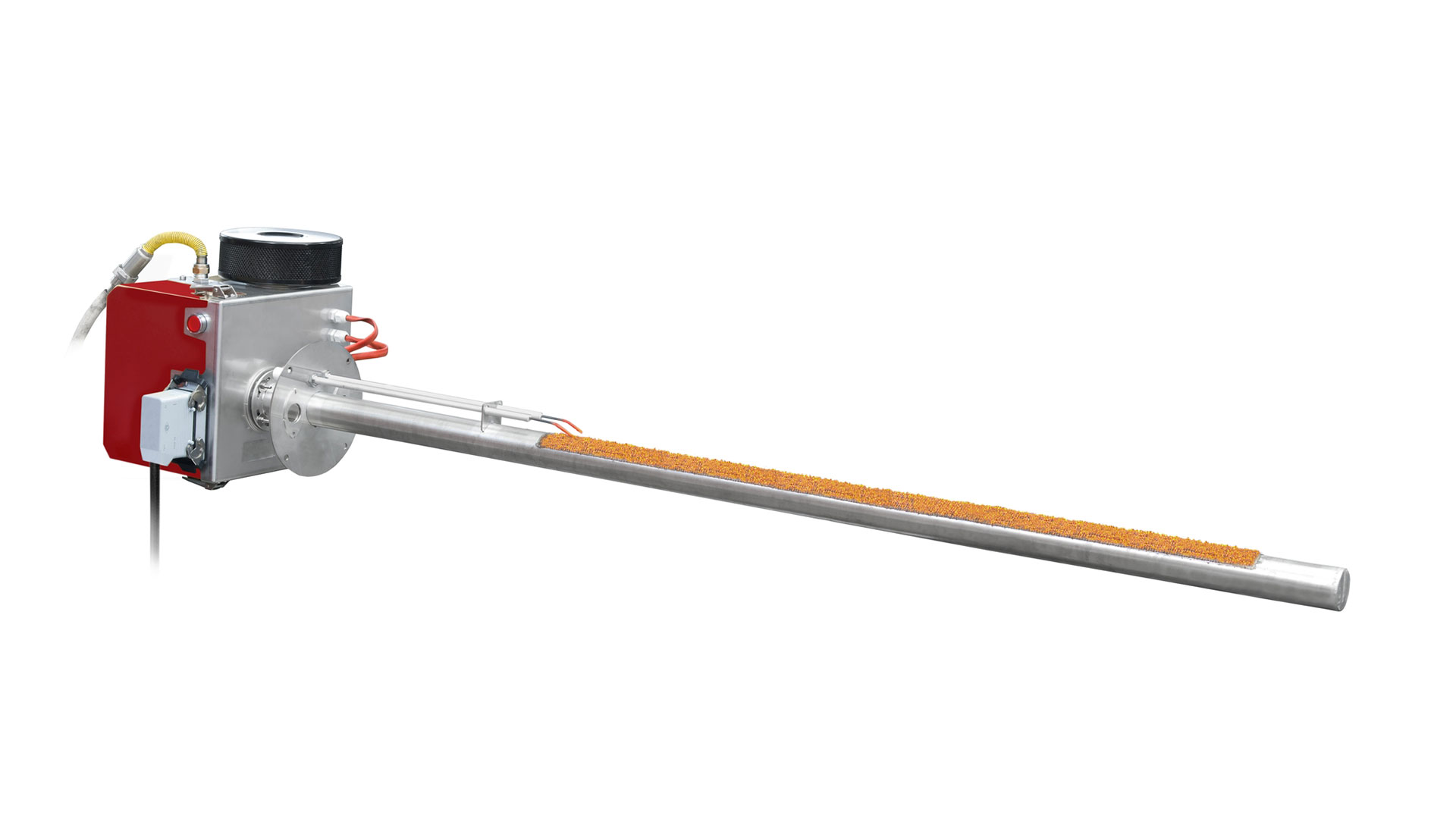

SIABS specialises in the design and manufacture of premix industrial burners for heat treatment, offering fully customised solutions for a wide range of production applications.By using high-performance metallic fibre, our burners adapt perfectly to every process requirement, ensuring efficiency, reliability and precise temperature control.

High-Performance Burners for Heat Treatment

SIABS burners are designed to reach temperatures exceeding 1000 °C, with fast power modulation up to 10000 kW/m².Their advanced technology ensures homogeneous combustion, extremely low pressure losses and constantperformance even in the most demanding thermal cycles.

Industrial Applications of SIABS Burners

Thanks to our long-standing experience, we have developed customised burner systems for a variety of industries, including:

- Heat treatment in the food industry

- Ceramic kilns and high-temperature processes

- Industrial painting and drying plants

- Textile and heat-setting processes

- Sheet pre-heating and metallurgical applications

- Other special thermalsystems upon request

Why choose SIABS burners for heat treatment:

- High-efficiency premix technology

- Rapid power modulation

- Temperatures exceeding 1000 °C

- Stable and homogeneous combustion

- Fully customised solutions

Tailor-Made Industrial Burners for Heat Treatment

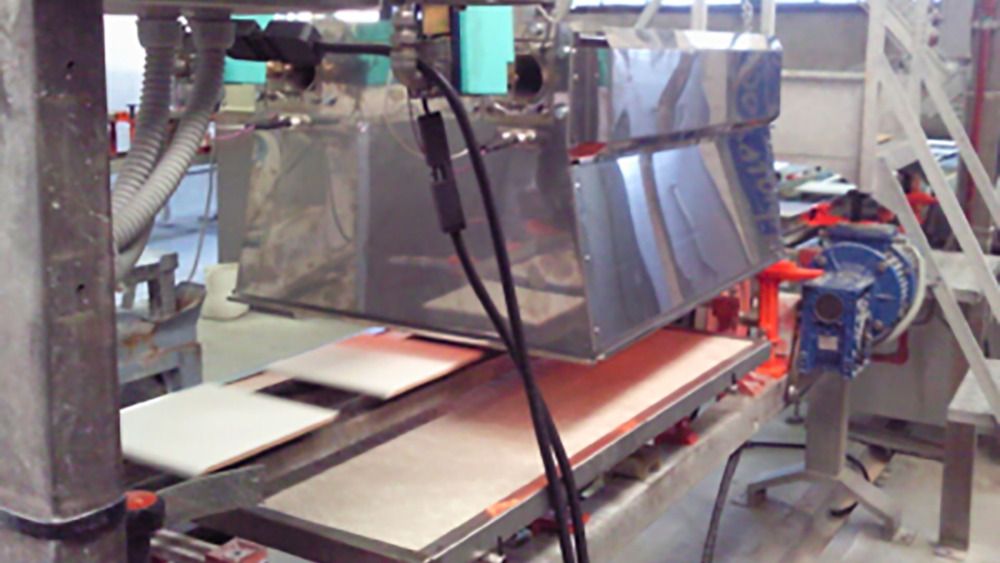

Our strength lies in custom design: each burner is developed according to the client’s technical specifications. We support our customers from the design phase to commissioning, ensuring maximum energy efficiency and optimised production processes.On request, a protectivebox for the gas group components can also be supplied.

A protective housing for the gas-control components can be supplied on request.

Our applications

Contact us today to discover the complete range of premix industrial burners for your specific application and receive tailored technical advice for your heat-treatment system.

Frequently Asked Questions about Industrial Burners

SIABS solutions are used across multiple industries — food, ceramics, textiles, metallurgy, chemicals and manufacturing — providing efficient and safe heating and burner systems.

SIABS guarantees high energy efficiency, reduced consumption, controlled emissions and long-term reliability, even in intensive production environments.Thanks to advanced technology, SIABS burners distribute heat evenly, ensuring constant performance and stable industrial processes.

– Metallic fibre adaptable to different process requirements

– Fast and wide power modulation up to 10,000 kW/m²

– Capability to reach temperatures over 1,000 °C

– Homogeneous combustion with low pressure losses

– Low NOx emissions

Absolutely. Their metallic fibre and modular design allow the burner to be tailored to specific production needs.

Yes. They are designed to withstand temperatures above 1000 °C, ensuring safety, stability and long lifespan even under extreme conditions.

Yes. SIABS premix burners allow precise and rapid power adjustment, perfectly adapting to the requirements of each heat-treatment process.

Request a quote

Discover our wide range of products and services, designed to keep your spaces comfortable all year round!

+39 02 90384081

commerciale@siabs.it

Viale del Lavoro, 7 20003 Casorezzo (MI)